Browse Our Collection

Get instant quotes that fit your budget perfectly.

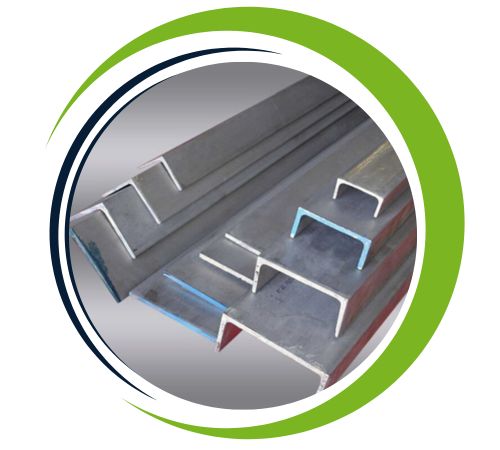

Kunj is a reliable producer and supplier of Hastelloy C276 channels in Delhi, India, providing corrosion-resistant solutions specially for harsh industrial conditions. Quality and performance-oriented, our Hastelloy C276 channels are engineered to operate under aggressive oxidizers, reducing agents, and extremely corrosive chemicals. Produced with high-quality raw material and advanced technology, these channels are of international standards and serve various industries such as chemical processing, marine, and pollution control. Kunj’s dedication to accuracy, strength, and customer satisfaction makes it an ideal option for clients who need strong materials for tough applications in harsh environments.

Hastelloy C276 is a nickel-chromium-molybdenum alloy with iron and tungsten additions. Its standard composition is about 57% Ni, 15.5% Mo, 14.5% Cr, 5% Fe, 3.5% W, and trace levels of Co, Mn, and Si. The alloy has a tensile strength of about 760 MPa, yield strength of 283 MPa, and elongation of 40%. It is exceptionally resistant to pitting, crevice corrosion, and stress corrosion cracking. All these properties along with thermal stability and weldability make Hastelloy C276 channels suitable for structural support in aggressive conditions and chemical containment systems.

| Specifications | : | ASTM B574 / ASME SB574 |

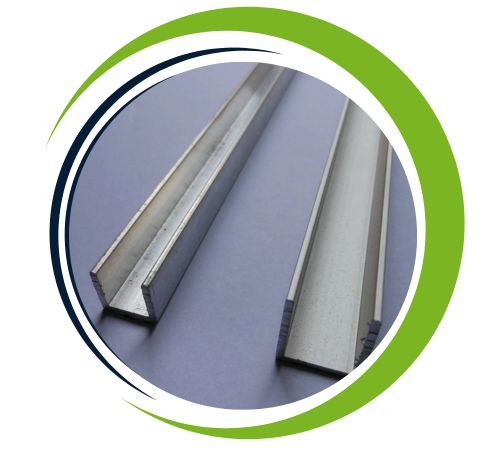

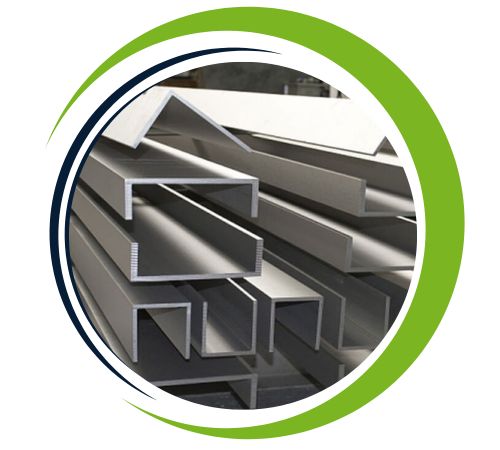

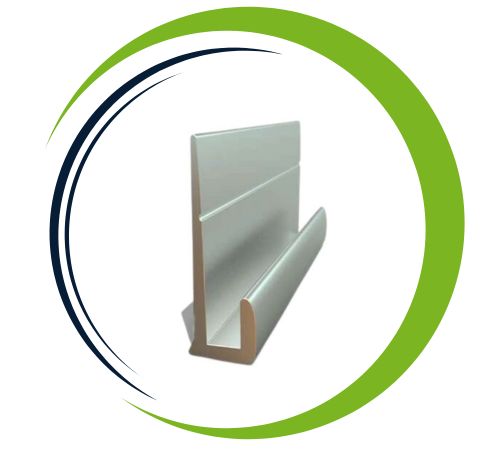

| Hastelloy C276 Channel | : | 40mm*20mm~300mm*300mm |

| Channel Thickness | : | 3 to 120 mm |

| Dimensions | : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Length | : | 3MTR, 4MTR, 5MTR, 6MTR, or Custom Cut Sizes |

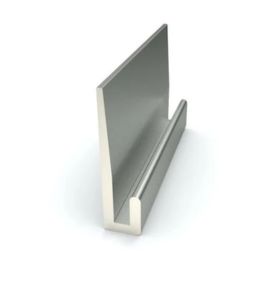

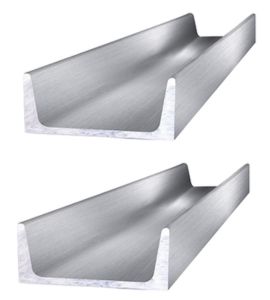

| Type | : | C Channel, U Channel, J Channel |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

| Grade | C | Mn | Si | Co | P | Fe | Mo | Ni | Cr | S | W | V |

| Hastelloy C276 | 0.010 max | 1 max | 0.08 max | 2.5 max | 0.04 max | 4 – 7 | 15 – 17 | Bal | 14.5-16.5 | 0.03 max | 3.0-4.5 | 0.35 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 790 | Psi – 52000 , MPa – 355 | 40% |

Kunj Sheets and Plates based in Chennai, India, is a leading supplier and stockist of high-quality metal products, including Sheets, Plates, Coils, Foils, Angles, Channels, Circles and Slitting Coils all offered with exceptional service and tailored to meet our customers specific requirements. With a focus on delivering superior products, we cater to a wide range of industries, providing reliable solutions for diverse applications. Our extensive inventory includes Known for our unique finishing techniques and commitment to quality. We are dedicated to ensuring customer satisfaction through dependable service and top-notch products.

Hastelloy C276 Channels offer outstanding corrosion resistance, especially in harsh environments involving strong oxidizing and reducing agents. They effectively combat pitting crevice corrosion, and stress corrosion cracking, ensuring long-lasting performance. With excellent mechanical strength and thermal stability, these channels are suitable for high-temperature and high-pressure applications. Their exceptional weldability and ease of fabrication further enhance their versatility. Hastelloy C276 Channels are ideal for chemical processing marine environments, and pollution control systems, providing reliability and efficiency in demanding conditions. Their durability ensures reduced maintenance and downtime making them a cost-effective choice for critical industrial applications.

Yes, we offer custom sizes for Hastelloy C276 Channel to meet specific project needs. Our team at Kunj Sheets and Plates is dedicated to providing tailored solutions for all your requirements. For more details, contact us at sales@aaronsheetsplates.com.

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN | GOST | OR |

| Hastelloy C276 | 2.4819 | N10276 | NW 0276 | NiMo16Cr15W | ХН65МВУ | ЭП760 |

Hastelloy C276 channels find broad application in service where high corrosion resistance and structural integrity are needed. They protect tanks, vessels, and piping systems in chemical and petrochemical facilities that are exposed to aggressive acids and solvents. These channels are used in the marine sector in offshore platforms, desalination systems, and brine systems because of their superior seawater corrosion resistance. They are utilized in flue gas scrubbers, nuclear power reactors, and waste treatment plants. Their resistance to aggressive media and high mechanical strength provide them with a good option for structural frameworks in highly corrosive and high-temperature industrial environments.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Discover high-quality products tailored to meet your unique needs and preferences.

Get instant quotes that fit your budget perfectly.

Chennai, India

Copyright 2024 Kunj Sheet and Plates. All rights reserved