Browse Our Collection

Get instant quotes that fit your budget perfectly.

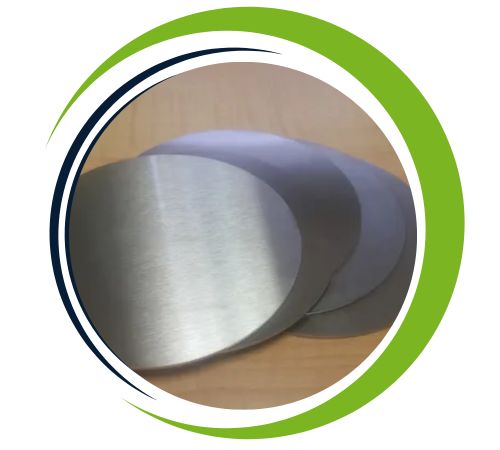

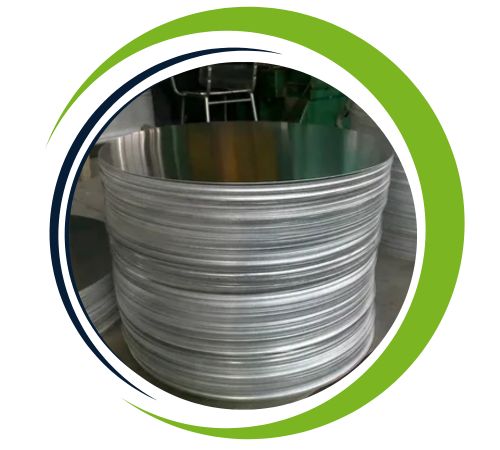

Kunj Sheets and Plates is a reliable and well-known producer and supplier of Inconel 690 Circles in Delhi, India. With a reputation for providing top-quality industrial metal products, Kunj provides precisely engineered circles that are made from high-quality-grade Inconel 690 alloy. With an unwavering focus on quality, innovation, and customer satisfaction, the company makes sure every product meets high international standards. Their Inconel 690 Circles find extensive demand due to their high strength, corrosion resistance, and ability to withstand high temperatures, making them suitable for demanding industrial applications. Kunj caters to various industries such as petrochemicals, power generation, and shipping industries with stable and long-lasting solutions.

Inconel 690 Circles consist mainly of nickel (58–63%), chromium (27–31%), and iron, along with minor content of silicon, manganese, and carbon. This nickel-based, high-chromium alloy has excellent resistance to oxidation and corrosion at high temperatures. It has a tensile strength of approximately 380–620 MPa and yield strength of about 170–310 MPa, while showing good elongation (≥30%). The alloy demonstrates fine mechanical stability even under high temperatures. Its weldability and low thermal expansion make it well adapted to demanding applications that both demand strength and require corrosion resistance for long service life.

| Specifications | ASTM B564, B446, B637 / ASME SB564, SB446, SB637 |

|---|---|

| Standard | DIN, ASTM, BS and all International Standards |

| Flat bar blocks | up to 27″ width and 15,000 lbs |

| Cylinders and sleeves | up to 50″ maximum O.D. and 65″ maximum length |

| Discs and hubs | up to 50″ diameter and 20,000 lbs |

| Rolled, hand forged or mandrel forged rings | up to 84″ maximum O.D. and 40″ maximum length |

| Rounds, shafts and step shafts | up to 144″ maximum length and 20,000 lbs |

| Forging Types | Impression Die Forging, Open Die Forging, Seamless Rolled Forging, Hot Forging, Cold Forging, Open die hammer forging, Impression die drop forging, Closed Die Forging, Press Forging, Upset Forging, Compression Forging, Swaging, Rotary Forging, Roll forging. |

| UNS | Werkstoff Nr. |

| N06690 | 2.4642 |

| Ni | Cr | Fe | Cu | Mn | Si | C | S |

| 58.0 min | 27.00 – 31.00 | 7.00 – 11.00 | 0.50 max | .50 max | 0.50 max | 0.05 max | 0.01 max |

| Density | 8.19 g/cm3 |

| Melting Point | 1343-1377 °C (2450-2510 °F) |

| Tensile Strength | MPa – 66.80 |

| Yield Strength (0.2%Offset) | MPa – 110 |

| Elongation | 39 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Kunj Sheets and Plates based in Chennai, India, is a leading supplier and stockist of high-quality metal products, including Sheets, Plates, Coils, Foils, Angles, Channels, Circles, and Slitting Coils, all offered with exceptional service and tailored to meet our customers specific requirements. With a focus on delivering superior products, we cater to a wide range of industries, providing reliable solutions for diverse applications. Our extensive inventory includes Known for our unique finishing techniques and commitment to quality. We are dedicated to ensuring customer satisfaction through dependable service and top-notch products.

Inconel 690 circles offer numerous advantages, making them ideal for demanding applications. Their exceptional resistance to oxidation and corrosion, especially in harsh chemical environments, ensures durability and long service life. The material withstands high temperatures and thermal cycling, making it suitable for use in heat exchangers, power plants, and nuclear reactors. Inconel 690 circles also exhibit excellent mechanical strength and stress corrosion cracking resistance, enhancing reliability under extreme conditions. Additionally, their versatility and weldability make them easy to fabricate for various industrial and engineering purposes.

Yes, we offer custom sizes for Inconel 690 Circle to meet specific project needs. Our team at Kunj Sheets and Plates is dedicated to providing tailored solutions for all your requirements. For more details, contact us at sales@aaronsheetsplates.com.

Inconel 690 Circles find extensive application in high temperature and corrosive conditions because of their superior resistance to oxidation, carburization, and aqueous corrosion. Typical applications are for steam generators, heat exchangers, nuclear reactors, and chemical processing plants. In the nuclear sector, they find frequent application in reactor core structures and pressurized water reactor steam generators. The circles also find application in gas turbines, petrochemical facilities, and marine engineering. Their structural integrity and stress reliability in extreme temperatures make them a necessity in industries where performance, durability, and safety are of paramount importance.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Discover high-quality products tailored to meet your unique needs and preferences.

Get instant quotes that fit your budget perfectly.

Chennai, India

Copyright 2024 Kunj Sheet and Plates. All rights reserved