Browse Our Collection

Get instant quotes that fit your budget perfectly.

Based in Delhi, India, Kunj Sheets and Plates is a top manufacturer and supplier of SMO 254 Sheet and Plates, providing high-quality austenitic stainless steel for extremely corrosive environments. SMO 254 is renowned for its exceptional resistance to stress corrosion cracking caused by chloride, pitting, and crevice corrosion. Our SMO 254 plates are extensively utilised in offshore, marine, and chemical processing applications where superior corrosion resistance and high strength are crucial. Kunj Sheets and Plates provides high-performance SMO 254 steel solutions to industries in India and around the world with stringent quality control, timely delivery, and an emphasis on customer satisfaction.

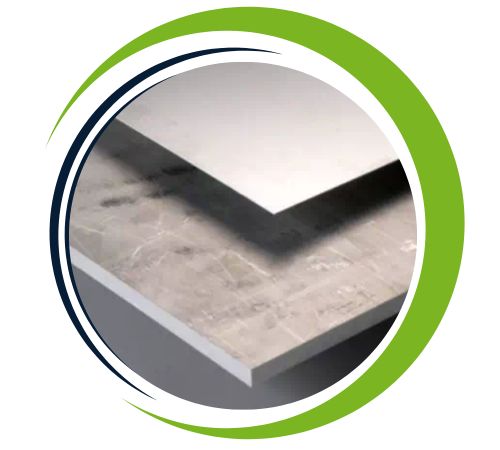

High-alloy austenitic stainless steel SMO 254 (UNS S31254) has about 20% chromium, 18% nickel, 6% molybdenum, and nitrogen. In extremely acidic and chloride-rich environments, this special composition offers exceptional corrosion resistance. SMO 254 has a high elongation and impact strength, a tensile strength of up to 650 MPa, and a yield strength of about 300 MPa. It is appropriate for welding and forming and retains its toughness and ductility even at low temperatures. Its metallurgical structure makes it perfect for demanding service conditions and provides remarkable resistance to stress corrosion cracking.

| Specifications | ASTM A240 / ASME SA240 |

| Thickness | 4mm-100mm |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hairline, sand blast, Brush, etching, etc |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Grade | Ni | C | Mo | Mn | Si | Fe | Cu | S | P | Cr |

| SMO 254 | 17.5 – 18.5 | 0.02 max | 6 – 6.5 | 1 max | 0.8 max | – | 0.5 – 1 | 0.01 max | 0.03 max | 19.5 – 20.5 |

| 0.2% Proof Stress (N/mm2 ) [ksi] minimum | 300 [43.5] |

| Tensile Strength (N/mm2) [ksi] minimum | 650 |

| Elongation (%) minimum | 35 |

| Hardness (HBN) | 270 max |

| Reduction of Cross Section Area (%) | 50 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Kunj Sheets and Plates based in Chennai, India, is a leading supplier and stockist of high-quality metal products, including Sheets, Plates, Coils, Foils, Angles, Channels, Circles, and Slitting Coils, all offered with exceptional service and tailored to meet our customers specific requirements. With a focus on delivering superior products, we cater to a wide range of industries, providing reliable solutions for diverse applications. Our extensive inventory includes Known for our unique finishing techniques and commitment to quality. We are dedicated to ensuring customer satisfaction through dependable service and top-notch products.

DIN 1.4547 Sheets and Plates offer exceptional corrosion resistance, particularly against pitting, crevice corrosion, and stress corrosion cracking in chloride environments. With high molybdenum and nitrogen content, it performs excellently in harsh chemical and marine conditions. The alloy provides superior strength, durability, and excellent weldability, making it ideal for high-stress applications. Its resistance to high temperatures and aggressive environments ensures long-term performance without degradation. SMO 254 is also highly resistant to oxidation, ensuring it maintains its integrity even in extreme conditions, making it a preferred choice for industries such as chemical processing, petrochemical, and marine.

| Density (Kg.m-1) | 8000 |

| Magnetic Permeability | <1.05 |

| Young’s Modulus (N/mm2) | 200 x 103 |

| Specific Heat, 20°C (J.Kg-1.°K-1) | 500 |

| Specific Electrical Resistance, 20°C (µO.m) | 0.85 |

| Thermal conductivity, 20°C | 13.5 |

Yes, we offer custom sizes for SMO 254 Sheet and Plates to meet specific project needs. Our team at Kunj Sheets and Plates is dedicated to providing tailored solutions for all your requirements. For more details, contact us at sales@kunjsheetsandplates.co.in.

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | SIS | GOST |

| SMO 254 | S31254 | 1.4547 | Z1 CNDU 20.18.06Az | X1CrNiMoCuN20-18-7 | – | 2378 | – |

| Surface finish | Thickness (mm) | Width (mm) |

|---|---|---|

| 2B – Cold rolled, heat treated, pickled, skin passed | 0.25–8.0 | max. 2032 |

| 2D – Cold rolled, heat treated, pickled | 0.4–6.35 | max. 1524 |

| 2E – Cold rolled, heat treated, mechanically descaled | 0.4–8.0 | max. 2032 |

| 2R – Cold rolled, bright annealed | 0.25–3.5 | max. 1524 |

| 2H – Work hardened | 0.4–6.35 | max. 1524 |

| Polished, brushed | 0.5–4.0 | max. 1524 |

Applications needing strong mechanical performance and high corrosion resistance use SMO 254 Sheets and Plates. They are extensively used in pulp and paper production, chemical processing, desalination facilities, heat exchangers, and seawater handling systems. The material is perfect for food processing equipment, flue gas cleaning systems, and marine engineering because of its resistance to acids and chlorides. SMO 254 is also preferred for reactors, tanks, and pressure vessels in the petrochemical and pharmaceutical industries. Its exceptional formability and weldability enable the production of intricate components and guarantee durability in the most demanding service conditions.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Discover high-quality products tailored to meet your unique needs and preferences.

Get instant quotes that fit your budget perfectly.

Chennai, India

Copyright 2024 Kunj Sheet and Plates. All rights reserved