Browse Our Collection

Get instant quotes that fit your budget perfectly.

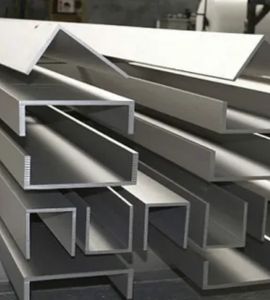

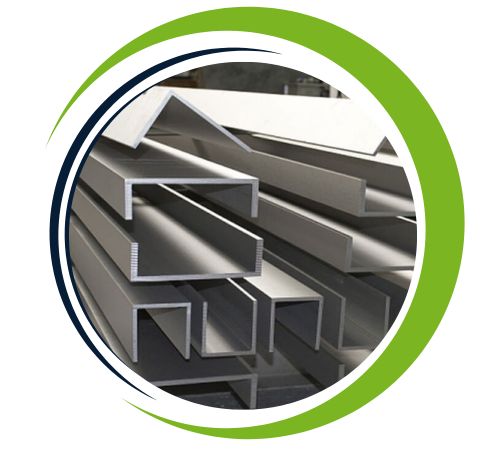

Kunj Sheets and Plates, based in Delhi, India, is a prominent producer and supplier of high-grade stainless steel items tailored for rigorous industrial application. Their Stainless Steel 316H Channels are designed for best-in-class performance under high-temperature and corrosive conditions. Renowned for precision production, consistent quality, and compliance with international standards, Kunj serves industries like chemical processing, power generation, construction, and shipping. With state-of-the-art production facilities and a culture of excellence, Kunj Sheets and Plates provides stainless steel solutions that provide strength, durability, and long-term reliability in applications of crucial support and structure.

Stainless Steel 316H Channel is a high-carbon modification of SS 316 that is intended to provide greater strength and creep resistance at higher temperatures. Its content consists of Chromium (16–18%), Nickel (10–14%), Molybdenum (2–3%), Carbon (0.04–0.10%), Manganese (≤2%), Silicon (≤1%), and the remainder Iron. The carbon addition enhances high-temperature tensile and yield strength with still excellent corrosion resistance, especially against chlorides and reducing acids. It has a tensile strength of approximately 515 MPa, yield strength of 205 MPa, and elongation of 40%. SS 316H maintains its mechanical properties in high-temperature and high-pressure conditions, making it suitable for structural applications.

| Standard | ASTM A276, ASTM A479 / ASME SA276, ASME SA479 |

| Condition | HRAP |

| Size Range | Base: 80 to 150 mm Side: 40 to 75 mm |

| Thickness | 5 to 6 mm (depending on size) |

| Grades | 304, 316 |

| Processing | Bar cutting |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 |

| SS 304L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 – 20 | – | 8 – 13 |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 1.0 max | 16.00 – 18.00 | 16.00 – 18.00 | 10.00 – 14.00 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Kunj Sheets and Plates based in Chennai, India, is a leading supplier and stockist of high-quality metal products, including Sheets, Plates, Coils, Foils, Angles, Channels, Circles, and Slitting Coils, all offered with exceptional service and tailored to meet our customers specific requirements. With a focus on delivering superior products, we cater to a wide range of industries, providing reliable solutions for diverse applications. Our extensive inventory includes Known for our unique finishing techniques and commitment to quality. We are dedicated to ensuring customer satisfaction through dependable service and top-notch products.

Stainless Steel 316H channels offer exceptional advantages, especially in high-temperature and corrosive environments. With a high content of chromium, nickel, and molybdenum, they provide outstanding resistance to oxidation, pitting, and stress corrosion. The low carbon content enhances weldability and reduces the risk of carbide precipitation, making them ideal for welding in demanding applications. These channels maintain strength and durability at elevated temperatures, making them suitable for use in heat exchangers, furnaces, and industrial equipment. Additionally, their long-lasting performance, low maintenance requirements, and versatility make them a reliable choice for various industries.

Yes, we offer custom sizes for Stainless Steel 316H Channel to meet specific project needs. Our team at Kunj Sheets and Plates is dedicated to providing tailored solutions for all your requirements. For more details, contact us at sales@kunjsheetsandplates.co.in.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | – | 03Х18Н11 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| Description | Process | G kg/m | h mm | b mm | tw mm | tf mm | r1 mm | r2 mm |

|---|---|---|---|---|---|---|---|---|

| C 50X25X5X6 | Hot Rolled | 3.95 | 50 | 25 | 5 | 6 | 6 | 3 |

| C 75X40X5X7 | Hot Rolled/Laser | 6.95 | 75 | 40 | 5 | 7 | 8 | 4 |

| C 100X50X5X7.5 | Hot Rolled/Laser | 9.37 | 100 | 50 | 5 | 7.5 | 8 | 4 |

| C 125X65X6X8 | Hot Rolled/Laser | 13.4 | 125 | 65 | 6 | 8 | 8 | 4 |

| C 150X75X6.5X10 | Hot Rolled/Laser | 18.62 | 150 | 75 | 6.5 | 10 | 10 | 5 |

| C 150X75X9X12.5 | Hot Rolled/Laser | 24.01 | 150 | 75 | 9 | 12.5 | 5 | 1 |

| C 180X75X7X10.5 | Hot Rolled/Laser | 21.52 | 180 | 75 | 7 | 10 | 2 | 1 |

| C 200X80X7.5X11 | Hot Rolled/Laser | 24.77 | 200 | 80 | 7.5 | 11 | 2 | 1 |

| C 200X90X8X13.5 | Hot Rolled/Laser | 30.53 | 200 | 90 | 8 | 13.5 | 2 | 1 |

| C 230X80X8X12 | Hot Rolled/Laser | 28.56 | 230 | 80 | 8 | 12 | 2 | 1 |

| C 250X90X9X13 | Hot Rolled/Laser | 34.86 | 250 | 90 | 9 | 13 | 2 | 1 |

| C 250X90X11X14.5 | Hot Rolled/Laser | 40.34 | 250 | 90 | 11 | 14.5 | 2 | 1 |

| C 300X90X9X12 | Hot Rolled/Laser | 37.17 | 300 | 90 | 9 | 12 | 2 | 1 |

| C 300X90X10X15.5 | Hot Rolled/Laser | 43.85 | 300 | 90 | 10 | 15.5 | 2 | 1 |

| C 300X90X12X16 | Hot Rolled/Laser | 48.78 | 300 | 90 | 12 | 16 | 2 | 1 |

| C 380X100X10.5X16 | Hot Rolled/Laser | 54.85 | 380 | 100 | 10.5 | 16 | 2 | 1 |

| C 380X100X13X16.5 | Hot Rolled/Laser | 62.5 | 380 | 100 | 13 | 16.5 | 2 | 1 |

| C 380X100X13X20 | Hot Rolled/Laser | 67.37 | 380 | 100 | 13 | 20 | 2 | 1 |

Stainless Steel 316H Channels are used extensively in high-temperature, pressure, and aggressive chemical exposure applications. Typical applications include heat exchangers, pressure vessels, boilers, condensers, and process equipment handling high temperatures. The molybdenum content in the alloy gives it superior resistance to pitting and crevice corrosion in environments with a high content of chlorides like marine and coastal constructions. SS 316H Channels find applications in oil and gas refineries, petrochemical industries, and power plants where long-term corrosion resistance and structural integrity are required. Their weldability, strength, and resistance to wear and tear make them excellent for support structures, fabrication, and heavy industrial installations.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Discover high-quality products tailored to meet your unique needs and preferences.

Get instant quotes that fit your budget perfectly.

Chennai, India

Copyright 2024 Kunj Sheet and Plates. All rights reserved