Browse Our Collection

Get instant quotes that fit your budget perfectly.

Kunj Sheets and Plates is a leading manufacturer and supplier of S32750 Super Duplex Steel circles in Delhi, India, providing precision-engineered products for challenging industrial uses. Our S32750 Super Duplex circles are renowned for their high strength, excellent corrosion resistance, and sustainability even under the most extreme conditions. Produced using sophisticated methods and quality-inspected materials, these circles are compliant with international standards and specifications. We cater to a wide range of industries such as chemical processing, marine, desalination, and oil & gas, offering customized solutions that maintain long-term performance, structural integrity, and cost-effectiveness for critical operations.

Super Duplex Steel S32750 circles are manufactured with a highly alloyed stainless steel grade with 24–26% Chromium, 6–8% Nickel, 3–5% Molybdenum, and a minor addition of Nitrogen. This balanced alloy offers better resistance to chloride pitting, crevice corrosion, and stress corrosion cracking. The circles have good mechanical properties with a minimum tensile strength of 795 MPa, a yield strength of 550 MPa, and elongation of approximately 15%. S32750 circles are consequently well suited to application in high-pressure and corrosive conditions where normal stainless steels could fail.

| Specifications | ASTM A240 / ASME SA240 |

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Thickness | 1 mm To 100 mm |

| Diameter | Upto 2000 mm |

| Circle | 3″ DIA up to 38″ DIA 1500 lbs max |

| Rings | 3″ OD up to 48″ OD Up to 900 lbs max |

| Cutting | Plazma & Machined Cut |

| Finish | HR, CR, 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

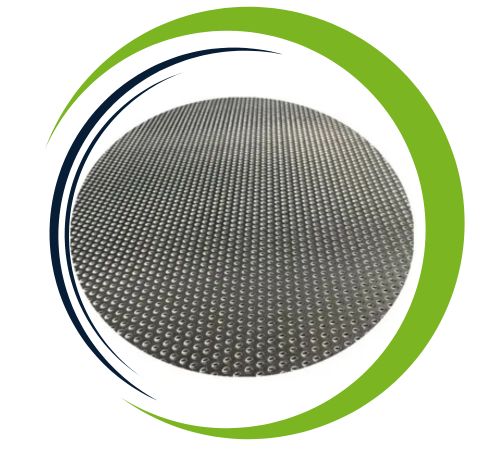

| Form | Cold Rolled Circle, Small Flat Circle, Industrial Circle, Perforated Circle, Forged Steel Circles, Cnc Finish Circle, Polished Unique Circle, Hot Rolled Circle, Fey Laminar Rings, Proof Machined Rings, Cold Rolled Rings, Hot Rolled Rings, McInnes Rolled Rings, Die-Formed Rings, Forging Rings, CNC Machined Rings. |

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex S32750 | 1.4410 | S32750 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S32750 | 7.8 | 0.281 | 1350 | 2460 |

Kunj Sheets and Plates based in Chennai, India, is a leading supplier and stockist of high-quality metal products, including Sheets, Plates, Coils, Foils, Angles, Channels, Circles, and Slitting Coils, all offered with exceptional service and tailored to meet our customers specific requirements. With a focus on delivering superior products, we cater to a wide range of industries, providing reliable solutions for diverse applications. Our extensive inventory includes Known for our unique finishing techniques and commitment to quality. We are dedicated to ensuring customer satisfaction through dependable service and top-notch products.

Super Duplex S32750 Circle offers several advantages, making it ideal for demanding applications. Its exceptional corrosion resistance, particularly against pitting, crevice, and stress corrosion cracking, ensures longevity in harsh environments, including marine and chemical industries. The alloy’s high tensile and yield strength provide excellent durability and reliability, even under high pressure. Its balanced microstructure of austenite and ferrite enhances mechanical properties, making it highly resistant to fatigue and wear. Additionally, Super Duplex S32750 offers good weldability and is suitable for high-temperature applications, ensuring superior performance and extended service life.

Yes, we offer custom sizes for Super Duplex Steel S32750 Circle to meet specific project needs. Our team at Kunj Sheets and Plates is dedicated to providing tailored solutions for all your requirements. For more details, contact us at sales@kunjsheetsandplates.co.in.

| Size | 18 G. | 19 G. | 20 G. | 22 G. | 24 G. | 26 G. |

| .4.5 | .0-107 | 0-085 | 0-080 | 0-062 | 0.049 | 0-040 |

| 5 | 0-120 | 0-095 | 0-090 | 0-070 | 0-055 | 0-045 |

| 5.5 | 0-146 | 0-119 | 0-109 | 0-085 | 0-066 | 0-054 |

| 6 | 0-172 | 0-136 | 0-130 | 0-100 | 0-079 | 0-064 |

| 6.5 | 0-200 | 0-153 | 0-150 | 0-128 | 0-093 | 0-074 |

| 7 | 0-235 | 0-190 | 0-176 | 0-136 | 0-107 | 0-088 |

| 7.5 | 0.270 | 0.212 | 0.201 | 0-157 | 0-123 | 0-100 |

| 8 | 0-307 | 0-240 | 0-230 | 0-180 | 0-140 | 0-115 |

| 8.5 | 0-347 | 0-270 | 0-262 | 0-202 | 0-156 | 0-130 |

| 9 | 0-388 | 0-330 | 0-301 | 0-230 | 0-178 | 0-145 |

| 9.5 | 0-472 | 0-342 | 0-324 | 0-252 | 0-198 | 0-162 |

| 10 | 0-480 | 0-380 | 0-360 | 0-280 | 0-220 | 0-180 |

| 11 | 0-580 | 0-450 | 0-435 | 0-338 | 0-266 | 0-218 |

| 12 | 0-690 | 0-540 | 0-518 | 0-403 | 0-318 | 0-253 |

| 13 | 0-811 | 0-640 | 0-508 | 0-608 | 0-371 | 0-304 |

| 14 | 0-940 | 0-750 | 0-708 | 0-558 | 0-430 | 0-352 |

| 15 | 1-080 | 0-860 | 0-808 | 0-650 | 0-495 | 0-405 |

| 16 | 1-228 | 0-960 | 0-921 | 0-736 | 0-563 | 0-460 |

| 17 | 1-382 | 1-080 | 0-940 | 0-809 | 0-635 | 0-560 |

| 18 | 1-595 | 1-200 | 1-116 | 0-907 | 0-712 | 0-683 |

| 19 | 1-732 | 1-350 | 1-300 | 1-010 | 0-794 | 0-750 |

| 20 | 1-920 | 1-400 | 1-340 | 1-120 | 0-880 | 0-785 |

| RAW MATERIAL | MAX. HARDNESS | TEMPERATURE | ABBREVIATIONSMARKER | |

| BRUCELLOSIS | ROCKWELL | |||

| SOFT IRON | 90 | 56 | -60 540 | D |

| LOW CB STEEL | 120 | 68 | -40 540 | S |

| 304SS | 160 | 83 | -250 700b | 304 |

| 304LSS | 150 | 83 | -250 450 | 304L |

| 316SS | 160 | 83 | -200 700b | 316 |

| 316LSS | 150 | 83 | -200 450 | 316L |

| 321SS | 160 | 83 | -200 700b | 321 |

| 347SS | 160 | 83 | -200 700b | 347 |

| 410SS | 170 | 86 | -40 650 | 410 |

| 5Cr-0.5Mo | 130 | -29 650 | ||

| COPPER | 80 | -100 315 | ||

| ALUMINUM | 35 | -200 425 | ||

| INCONEL 600 | 150 | -100 1095 | ||

| INCOLOY 825 | 160 | -100 1095 | ||

| MONEL 400 | 150 | -100 760 | ||

| TITANIUM | 215 | -200 540 | ||

| NICHEL 200 | 110 | -200 760 | ||

| HASTELLOY C276 | 200 | -100 1095 | ||

Super Duplex Steel S32750 rings find applications in a broad array of processes where the requirements are both high mechanical strength and superior corrosion resistance. Some typical applications involve flanges, fittings for pipes, valve parts, gaskets, and heat exchanger components for the chemical, oil & gas, and petrochemical sectors. Applications in marine engineering, pulp and paper manufacture, seawater desalination, as well as offshore structural parts, are also favorable. Their resilience against harsh conditions and aggressive chemicals makes them perfect for long-term application in high-stress and corrosive systems, providing safety, efficiency, and durability for critical infrastructure.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Discover high-quality products tailored to meet your unique needs and preferences.

Get instant quotes that fit your budget perfectly.

Chennai, India

Copyright 2024 Kunj Sheet and Plates. All rights reserved